Radiation cross-linked hydrogels(RCHs) contain up to 90% water, which makes them highly heat-consuming and, therefore, instantly cool and, as a result, anesthetize the wound immediately after application. The cooling mode is maintained for a long time due to the evaporation of water from the surface of the dressing with a corresponding decrease in wound temperature.

RCHs is capable of absorbing and releasing fluids, which allows it to be used for infusion (injection) of drugs into the wound and for the absorption of its physiological secretions. It is possible to saturate the RCHs with the right type of medicine before applying it to the wound by soaking the dressing for 2-3 hours in a solution of the appropriate antiseptic, analgesic or analgesic. As a result, the bandage will gradually release the medicine into the wound over several hours. At the same time, the phenomenon of counter-diffusion is also possible, as a result of which, simultaneously with the release of drugs into the wound, the dressing absorbs physiological secretions of the wound and pus.

It should be emphasized that the function of infusion of pharmaceuticals into the wound is not the main advantage of RCHs over traditional types of dressings. The main advantage is a significant acceleration of healing by creating and maintaining a moist environment on the wound surface. Provided that the primary wound treatment (washing, disinfection) is performed properly, the application of RCHs dressing provides optimal conditions for healing without additional medications. The fact is that the human body consists of about 80% water and all vital metabolic processes take place in it only in the aquatic environment. One of the many functions of our skin is to keep this environment from leaking and drying out, and to protect it from the penetration of external microorganisms. The purpose of any medical bandages and dressings is to restore these functions in areas of skin damage.

The main difference between RCHs dressings and most traditional dressings is that the wound surface is immediately exposed to a moist environment under a layer of sterile RCHs. This avoids the formation of a crust from blood, lymph and dry materials of textile dressings and does not injure the wound by peeling off this crust every time the dressing is changed. Wet does not stick to wet, so RCHs does not form a crust on the wound, and can be removed completely painlessly without injuring the newly formed tissue. In addition to accelerating healing, it significantly reduces scarring.

Radiation-crosslinked hydrogel materials can be produced both already saturated with medically active agents and “neutral” materials with the ability to be saturated with any medications required in each case. It is technologically possible to saturate a radiation-crosslinked hydrogel with pharmacological agents at the manufacturing stage. That is, it is possible to manufacture a medically active dressing based on RCHs. However, this leads to a decrease in the versatility of such a product, because in one case or another, different medically active agents may be required in outpatient settings.

RCHs are transparent enough to monitor the wound without removing the dressing, i.e. without the risk of compromising wound sterility, which is especially important in the field.

Another extremely important factor is the ability to change the properties of RCHs within a wide range, depending on the specific disease and method of application. For example, in hydrogel dressings intended for field use, it is possible to increase their elasticity many times over (to prevent accidental disruption of the structure, which can lead to the ingress of microbes on the wound surface) and saturate the dressing with a solution of anesthetic. While in outpatient settings, elasticity is not an important parameter. In addition, in an outpatient setting, a doctor should be able to choose the active ingredient, so in this case, the dressing should be able to absorb and “release” the wound with medicinal solutions, which is not so important in the field. Therefore, RCHs is quite versatile and can serve both as a “neutral” matrix for filling with active substances selected for a particular case and as a completely independent element that facilitates and accelerates the wound healing process. The range of properties of hydrogel materials can be changed within a fairly wide range.

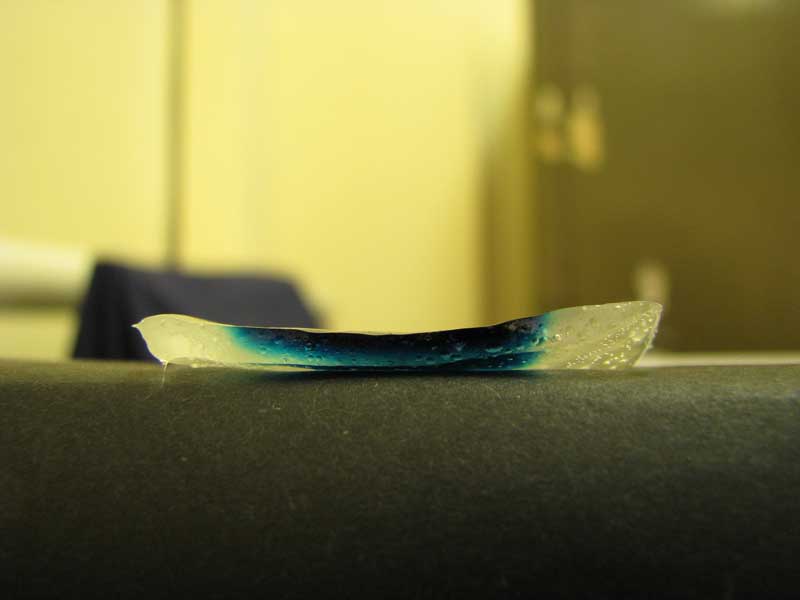

As already mentioned, RCHs are elastic, which ensures a tight fit of the dressing to the wound on any part of the body. The dressing easily conforms to the shape of the surface, can be stretched and restored to its original shape.

One of the most significant advantages of radiation-crosslinked hydrogel material over conventional textile material is its impermeability to microbes. RCHs have a cellular structure with a characteristic size much smaller than that of bacteria. Therefore, bacteria and germs are literally unable to penetrate from the outer layers of the dressing, which they have come from the environment, to the inner layers that are in contact with the wound. Therefore, when such a dressing is in close contact with the wound, the hydrogel material literally seals the wound, preventing the penetration of microbes, but provides diffusion of air and medicines to the skin surface.

It is important to note that RCHs is resistant to temperature effects in the range of 0 to 100 °C. At temperatures below 0 degrees Celsius, the RCHs dressing freezes due to the fact that it consists almost entirely of water, which turns to ice at negative temperatures. However, if the dressing is placed at room temperature after such “freezing”, it will thaw, regain all its physical properties and be ready to be applied to the wound.